WATER STORAGE

Fire Sprinkler Tanks

Overview

If you have any questions, feel free to call us or use our quote form

To speak to one of our agents online, click here

LPCB Approved Sprinkler Tanks

The strict regulations stated in LPS 1276 Issue 2.0 standard serve as a guideline for all fire sprinkler protection systems. This is a result of the increased number of fires and the extensive damage they cause.

For a sprinkler system to be effective it has to be designed, installed and maintained the right way. The LPS 1048-1 scheme states the requirements for the approval of Sprinkler Contractors in the UK and Ireland, ensuring that installers are capable of designing, installing, and servicing sprinkler systems to acceptable installation standards.

Sprinkler systems were originally developed for the protection of property or equipment, however, in recent years they have been used for the purpose of life safety as an aid to the means of escape of personnel. Sprinkler tanks are multifunctional and support fire detection systems, fire alarms and aid in fire suppression.

Sprinkler Tank Capacity

Tricel Weston’s sprinkler tanks range in capacity up to 1,300m3. The water capacity is dependent on a number of factors applicable to individual applications. The sprinkler tank capacity is determined by the following:

- Duration of water supply

- Mains refill capabilities – refill duration limits are outlined in BS EN12845

- Wet or dry pipe system

- Range between the highest and lowest sprinkler. Sprinkler design standard

- Full holding or reduced capacity – reduced capacity may be acceptable where the main refill capabilities are sufficient to make up the water requirement balance within the regulations for specific hazard classifications.

Fire Hazard Classification

Ordinary Hazard Group 1

Minimum full capacity 27,500 – 40,000 litres

Typically used for Hospitals, hotels, libraries (excluding book stores) restaurants, schools & offices. Data processing offices.

Ordinary Hazard Group 2

Minimum full capacity 105,000 – 140,000 litres

Typically used for laboratories, Laundries, car parks, leather goods factories & museums.

Ordinary Hazard Group 3

Minimum full capacity 135,000 – 185,000 litres.

Typically used for Broadcasting studios, railways stations, plant rooms, farm buildings. Department stores & shopping centres. Paper/cardboard/bookbinding factories.

Operational requirements of a BS EN 12845 & LPS1276 Issue 2.0 approved sprinkler tank.

The sprinkler tank shall provide water for automatic fire sprinkler systems.

The tank shall be designed such that the need for emptying the tank for first time maintenance shall be a period of not less than 10 years. This period excludes the need for maintenance caused by accidental damage or exceptional circumstances. Tanks should be subject to regular inspection and maintenance of ancillaries in-line with the Approved Companies’ specifications.

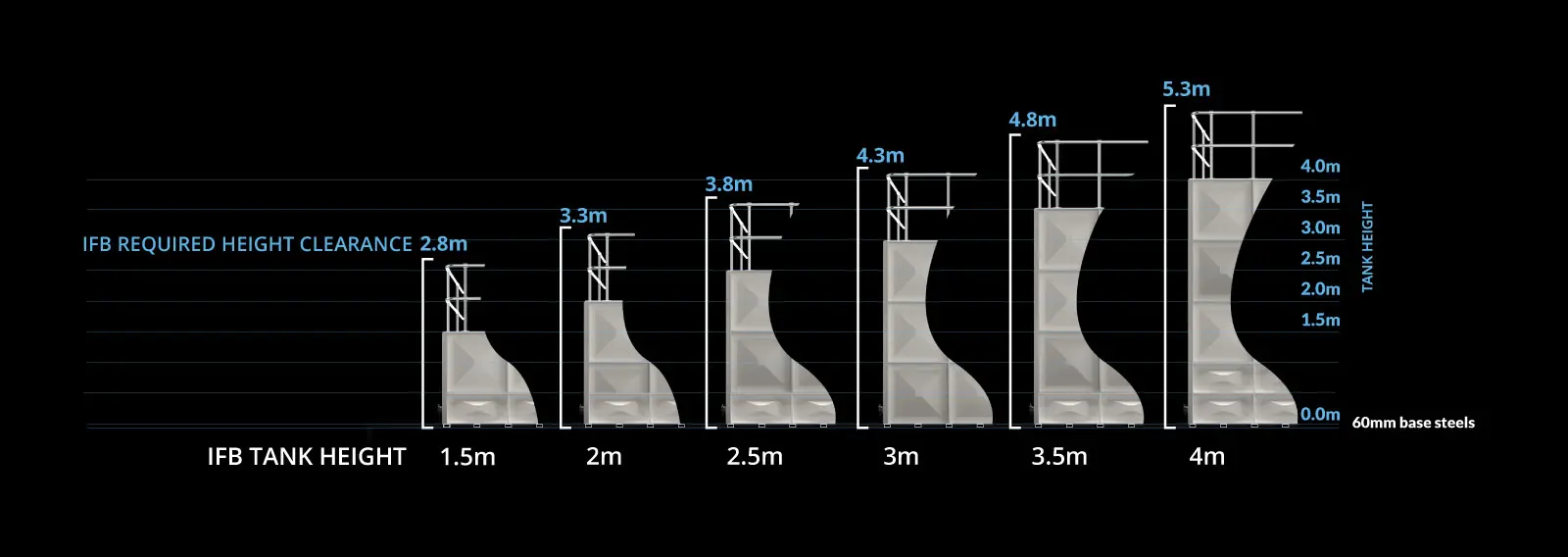

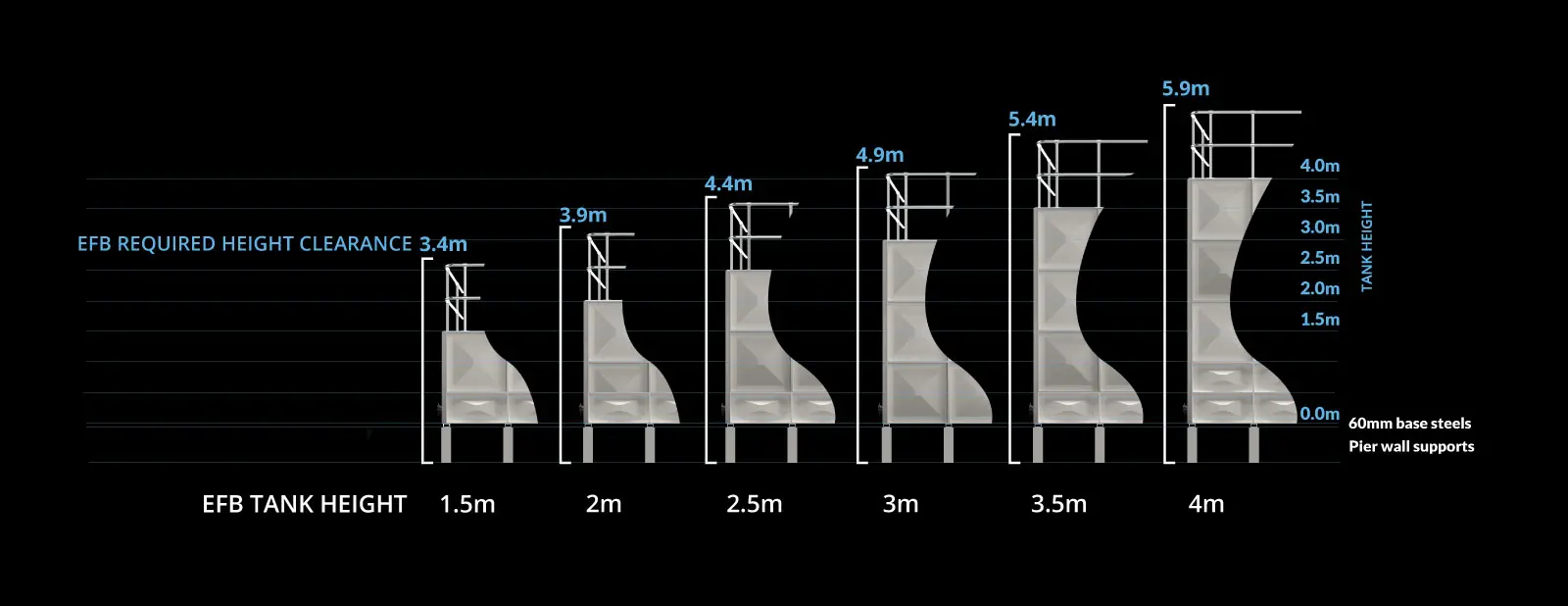

REQUIRED HEIGHT CLEARANCE WITH MANDATORY GUARDRAIL AND BASE STEELS

From the finished floor level (FFL) to the ceiling height.

Required Perimeter Clearance for IFB Tank

| TANK TYPE | TANK HEIGHT | CLEARANCE REQUIREMENT | HEIGHT CLEARANCE |

|---|---|---|---|

| IFB | 1.5m | 500mm | 2.8m |

| IFB | 2.0m | 500mm | 3.3m |

| IFB | 2.5m | 800mm | 3.8m |

| IFB | 3.0m | 800mm | 4.3m |

| IFB | 3.5m | 1000mm | 4.8m |

| IFB | 4.0m | 1000mm | 5.3m |

Required Perimeter Clearance for EFB Tank

| TANK TYPE | TANK HEIGHT | CLEARANCE REQUIREMENT | HEIGHT CLEARANCE |

|---|---|---|---|

| EFB | 1.5m | 500mm | 3.4m |

| EFB | 2.0m | 800mm | 3.9m |

| EFB | 2.5m | 800mm | 4.4m |

| EFB | 3.0m | 100mm | 4.9m |

| EFB | 3.5m | 1000mm | 5.4m |

| EFB | 4.0m | 1000mm | 5.9m |

Standard Ancillary Equipment

To enable personnel access for the maintenance and/or test of float or ball valves and other ancillary equipment, whilst keeping both feet on the platform, a permanently attached access ladder shall be provided for all tanks, which incorporates a platform and guard-rail. The ladder and access platforms shall conform to BS 4211. (images required)

Note: Where alternative access provision is required this will require separate approval by BRE Global.

To enable personnel to enter the tank, internal access ladders, where fitted, shall be designed to be corrosion resistant.

A ball or float valve for maintaining the required level of water in the tank shall be installed.

The valve shall be LPCB listed to LPS 2083 The Requirements and Test Procedures for the LPCB Approval of Automatic Water Level Control Valves for use in Above Ground Suction Tanks for Sprinkler Systems.

An access opening in the tank cover shall be provided. This shall be of such size and location to enable the testing, maintenance and replacement of the ball valve equipment. The cover of this opening shall be permanently attached by hinges or other means. It shall be securely latched when closed and be capable of being opened by hand.

The tank shall include a device to show the total amount of water present and which monitors the quantity of water down to below the suction pipe outlet to the pumps.

This device shall be capable of being maintained without draining the tank. The primary gauge shall be fitted to the external face of the tank at a height not greater than 1.75m from the tank base. Any additional remote readouts shall be suitable for use in the location in which are they are placed.

Note: “cat and mouse” type indicators are not accepted.

Refill rates for full capacity tanks in BS EN 12845 states that ‘The water source shall be capable of refilling the tank in no more than 36 hours’.

To view the available inlet valve flow rate chart for use in our LPS 1276 Issue 2.0 accredited sprinkler tanks, please view our chart here.

Any immersion heater provided must be of a type that shall not burn out when exposed to the air, e.g., when the water level in the tank is lowered below the immersion heater. The heater shall be of the dual element type. Each element shall be capable of operating independently and preventing water in the vicinity of the ball or float valves from freezing, to maintain the operational function of the tank. Each element shall be capable of being maintained or removed without draining the tank;

The provision of an immersion heater can be omitted only where the ambient water tank temperature around the ball or float valve can be maintained or shown not to drop below 4°C.

The tank shall be fitted with a drainage facility that will enable the tank to be emptied for maintenance and inspection purposes.

The tank shall be fitted with an outlet pipe to feed the sprinkler suction pumps. An LPCB approved (LPS 2070) Vortex Inhibitor shall be fitted to the inlet of the outlet pipe.

An overflow arrangement in compliance with the relevant water authority requirements shall be installed.

An access hatch at the base of the tank with a minimum opening of 600mm x 600mm or 600mm diameter shall be provided.

Where required, LPCB approved (LPS 1185) stop valves shall be used.

A level switch linked to the BMS to advise when the effective capacity volume has reduced by 10%.

Where balance pipes are installed, stop valves shall be fitted to enable isolation of each tank for maintenance. These valves shall be monitored.

60 years in business

A highly successful multinational corporation with over 60 years’ valuable industry experience

Fully Customisable Tanks

Tanks available for all capacities, 43 litres to 4,651,290 litres. Larger tanks available on request

Fast Delivery

On-time delivery is a core requirement of our successful business operations