Custom Moulding & SMC

Custom Equipment Enclosure for Sabre

Case study overview

Location

Cheshire UK

Project Type

Custom Moulding

Tricel solution

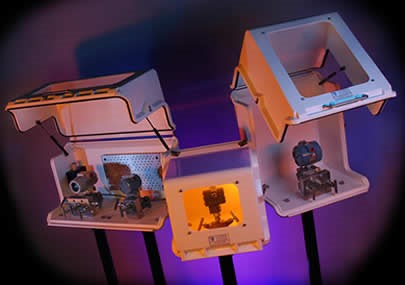

Custom Equipment enclosure providing a strong, reliable and durable solution for their instrument mounting and enclosure system

Request a quote for your project today!

The challenge

Sabre is leading Manufacturer of instrument valves, manifolds and instrumentation protection systems.

Sabre is an established provider of high quality, reliable solutions and a leading manufacturer of instrument valves, manifolds and instrumentation protection systems with over 60 years of successful experience. Their products are used by many of the world’s leading oil, gas, power and processing companies. Primary concerns for this client were safety in operation and long-term service dependability.

Weather proof Protection of the Sabor Equipment

Sabre required custom equipment enclosures in order to provide strong, reliable and durable for their instrument mounting and enclosure system. The systems which were to be housed were costly and sensitive, protection was paramount to the company’s expectations. This protection also needed to be highly resistant to weathering and changes in temperature as exposure to the element was a factor.

Protection from UV degradation

Furthermore, elements of the brief requirements were a strong heat-resistant quality to provide protection in the event of a fire as well as protection from ultraviolet (UV) degradation. UV was a concern as constant exposure to sunlight can cause products to crack or disintegrate. The instruments developed by Sabre are highly specialised and can be sensitive, and it was important to ensure they were safely protected from different types of exposure.

SMC Enclosure of Sabor Equipment

Tricel Solution

SMC Enclosure protecting the Sabre Equipment

Tricel is a well-established leading expert within the custom moulding industry with over 60 years of highly successful operations. With manufacturing capabilities in both the UK and Ireland, we develop and deliver innovative solutions to a wide range of industries. Using sheet moulding compounds and glass reinforced plastics we design and produce highly specialised products for multiple sectors.

Accordingly, we were able to deliver a complete system which met all their requirements with an SMC enclosure which offered excellent protection. The high strength to low weight ratio of the fibre reinforced composite material was highly durable, weather resistant, UV protected, and fire resistant and offered the form of security which was required for Sabre’s equipment enclosures.

The protective equipment enclosure was delivered in a specified off-white colour as requested. Products are pigmented to the individual requirements of clients to any colour which is necessary. Such products are also highly suited to post-production painting due to an ideal surface quality for top coat application

Call our technical sales team today!

The final result

To conclude, Sabre was extremely happy with the results of Tricel’s custom equipment enclosure, and we have continued to produce products for them for over 16 years. Today, these products are a key accessory in the supply and installation of a selection of Sabre installations.

If you are interested in our services, please contact our technical sales team who are standing by to answer any of your queries.

Get in touch to discuss your project.

Get a bespoke quote today

Key Features

SMC

A strong, durable and lightweight material

Expertise

A professional team with extensive experience

Cost-effective

Economical solutions for numerous products

Get in touch

Tricel (Gloucester) Limited.

Fox House, Stonedale Road, Stonehouse, Gloucester, GL10 3SA, United Kingdom.

Tel: +44 (0)1453 791 616